New Ammonia Conversion Marks Leap Forward for Green Hydrogen Energy

A recent breakthrough by a team from Waseda University and Yanmar Holdings introduces a new approach to low-temperature ammonia conversion, which could revolutionise the green energy industry.

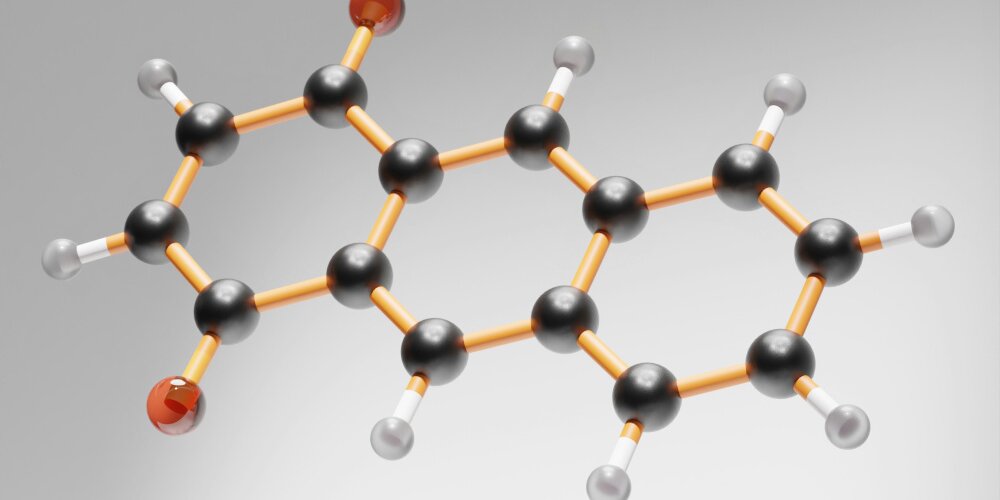

Despite it being the most abundant element in the known universe, hydrogen is mostly found in a bound state as chemical compounds, such as ammonia, metal hydrides, and other hydrogenated compounds.

Ammonia (NH3) is a highly efficient hydrogen carrier due to its high hydrogen density - 17.6% of its mass - and ease of liquefaction, and transportation. This makes it valuable for the green energy industry, as it can be decomposed to produce hydrogen gas without releasing CO2.

However, the challenge of using ammonia is that it requires extremely high temperatures (>773K) for decomposition reactions, making it impractical for widespread use. This high-temperature requirement poses a significant barrier to the adoption of ammonia as a green hydrogen source.

To solve this issue, a team at Waseda University, led by professor Yashushi Sekine, have developed a new compact process that could operate at a lower temperature. They achieved this by applying an electric field in the presence of a highly-active and readily-producible Ru/CeO2 catalyst.

“This is a collaborative project between our laboratory at Waseda University and Yanmar Holdings which is a leading company in ammonia utilization. We aimed to develop a process that would enable us to exploit the ability of ammonia to generate hydrogen on-demand,” said Sekine.

“We started investigating conventional thermal catalytic systems where the reaction proceeds through N and H adsorbate formation through dissociation of N-H bonds and the recombination of the adsorbates to form respective N2 and H2 gases”.

They observed the rate-determining step on an active metal Ru was the dissociation of N-H at high temperatures, and the desorption of nitrogen at low temperatures.

In attempting to overcome this issue, the team turned to electric field-assisted catalytic reactions, which improved the proton conduction at the surface of the Ru/CeO2 catalyst, and reduced the activation energy required for a reaction.

Armed with this information, the team created a thermal catalytic system for low-temperature decomposition of ammonia to hydrogen, assisted by the easily producible Ru/CeO2 catalyst and DC electric field.

The resulting decomposition was achieved at significantly-reduced temperatures (<473K) with 100% conversion rate achieved at 398K, surpassing the equilibrium conversion rate. The success was attributed to the electric field’s ability to promote surface protonics, lowering the apparent activation energies of the ammonia conversion reaction.

“We believe that our proposed method can accelerate the widespread adoption of clean alternative fuels by making the on-demand synthesis of CO2-free hydrogen easier than ever,” said Sekine.

Scanning Electron Microscopy at The Lab

Our Scanning Electron Microscope (SEM) is designed for flexible and complicated scopes of inspection. Equipped with low-vacuum capability, we are able to offer inspection of non-conducting samples without the need for coating.

To book an obligation-free consultation and find out how The Lab’s materials testing services can help and support you, contact our team today.

Discover our scanning electron microscopy today

For more information, the latest news, and industry insights, explore The Lab’s News and Knowledge Hub…

Groundbreaking New Research Could Be Cost-Effective Solution to Produce Green Hydrogen | LEBW Technique Used to Weld Full-Sized SMR Nuclear Vessel in 24 Hours | Researchers Find New Way to Weld Metal Foam Without Compromising the Material

- Date

- 04/12/2024