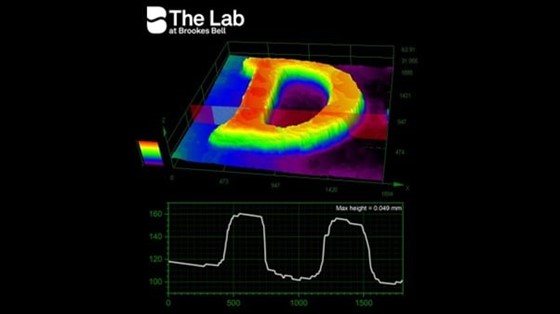

When you need a more in-depth understanding of your material or coating, whether that is to analyse the roughness of a material, steel pitting, the depth of corrosion or the blistering of your paint and coatings, you need profilometry or 3D reconstructions.

The Lab’s 3D reconstructions provide the much-needed detail that 2D scans and images can’t match. With roughness measurements accurate to 1 µm you can get the full picture, allowing you to make a fully informed decision about the state of your material.

Profilometry is a technique used to extract topographical data from a surface. This can be a single point, a line scan or even a full three-dimensional scan. The purpose of profilometry is to get surface morphology, step heights and surface roughness. This can be done using a physical probe or by using light. It is also useful for all material types: metals, polymers, ceramics, composites, rubbers etc and any combination thereof.

At The Lab at Brookes Bell, we opt for light using the state-of-the-art Olympus DSX1000 Digital Microscope, one of only a few in use in the UK.

Optical profilometry is a rapid, non-destructive, and non-contact surface metrology technique. Its key features and advantages include:

- Large selection of lenses that are easy to change

- Switch between 6 different observation methods by pushing a button

- Fast macro to micro viewing

- Accurate measurements with a telecentric optical system

- Advanced measurements are fast and easy to obtain

Our Olympus DSX1000 Digital Microscope has many technical advantages including:

- True imaging (area measurement, not serially point by point)

- Fast data acquisition over large areas

- Non-contact and non-destructive

- Large Z-axis range, from several nanometres up to feature heights as great as 7mm

- Variable field of view, 90µm up to 6mm (stitching is available)

- Critical dimension measurements (X, Y, and Z)

We work to ISO 5436-1:2000 Measurement Standards. This part of ISO 5436 is a Geometrical Product Specification (GPS) standard and is to be regarded as a general GPS standard. It influences the chain of standards on roughness, waviness and primary profile. Additionally, it specifies the characteristics of material measures used as measurement standards (etalons) for the calibration of metrological characteristics of instruments for the measurement of surface texture by the profile method as defined in ISO 3274.

Typical applications are endless, but examples include:

- Corrosion pitting

- Fracture surfaces

- Surface texture

- Thickness measurements and step height

- Paint blistering

- Machining

- Wear

- Scoring (including depth and width to identify size of particulate that caused the score)

To get the most accurate profilometry imaging for your investigation - from machinery to engine components, paints or coatings, plastics or composites, across all industries, please contact The Lab today.