Self-Healing Superhydrophobic Coating Delivers Unmatched Quality

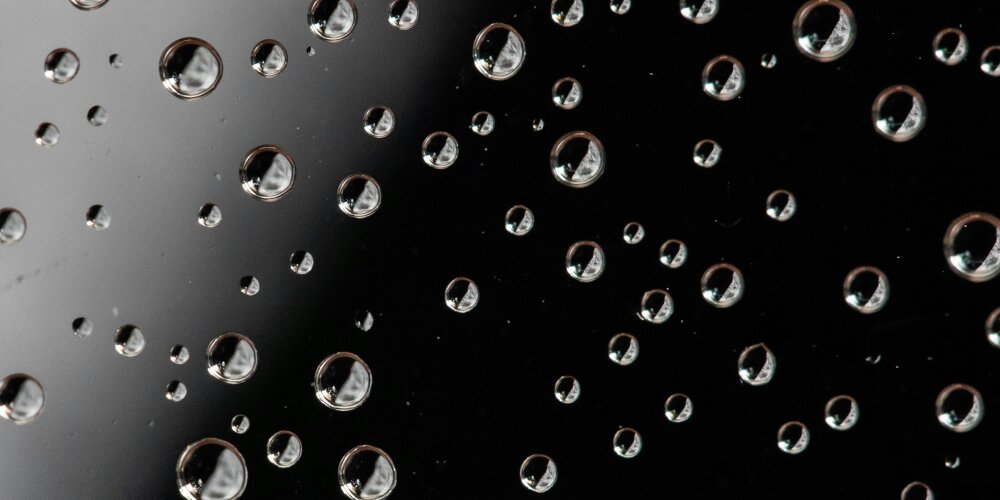

Researchers have made a huge advancement in material science with the development of a new self-healing superhydrophobic coating.

The coating - designed with a unique double-layer structure - promises excellent durability, resistance to friction and corrosion, and remarkable self-cleaning properties, making it an ideal solution for long-term protection in various applications.

The new coating is a result of meticulous research and development, combining epoxy resin (EP), polydimethylsiloxane (PDMS), and SiO2 nanoparticles. The distinctive double-layer structure plays a pivotal role in the coating’s performance.

By carefully varying the number of SiO2 nanoparticle layers, researchers have successfully achieved increased surface roughness and enhanced superhydrophobicity. This design maintains a low surface energy on the coating, making it highly resistant to water adhesion and capable of self-cleaning.

Extensive testing has demonstrated that the coating exhibits strong resistance to both corrosion and friction. As the number of SiO2 layers increases, so does the coating’s ability to withstand friction and corrosion. The coating even maintained its superhydrophobic properties even after being subjected to heavy abrasion with sandpaper.

Upon exposure to oxygen or argon etching, the coating is able to recover its superhydrophobicity. This self-repair mechanism is facilitated by the upward movement of hydrophobic groups and the restoration of bond intensity.

Coatings that underwent argon etching displayed superior self-healing performance, attributed to the increased Si-O-Si bond strength, ensuring the coating’s functionality over extended periods.

The potential applications of this advanced coating design are vast and varied. Industries where durability, corrosion resistance, and self-cleaning properties are crucial stand to benefit significantly from this innovation.

The marine, automotive, and industrial sectors, in particular, could see a transformation in their protective coating technologies, leading to improved performance and longevity of their products.

This advanced coating, which has been documented in an article titled “Self-healing superhydrophobic coating with longevity based on EP + PDMS/SiO2 bilayer structure design” in Organic Coatings journal, Volume 190, May 2024, shows the potential of this technology to revolutionise protective coatings.

The development of the self-healing superhydrophobic coating marks a significant milestone in material science. Its unique double-layer structure, combined with the impressive durability and self-healing capabilities, will prove vital for industries requiring superior protection against friction, corrosion, and other environmental factors.

Paint and coatings analysis at The Lab

Applying the right paints and coatings is crucial for preventing corrosion in vessels, vehicles, and equipment.

At The Lab, our skilled team employs advanced inspection tools to analyse flake samples and coating failures, identify the causes of breakdowns, and evaluate surface preparation before applying paint.

To learn more about our paint and coatings services, contact us today.

Learn more about our paint and coatings analysis services at The Lab

For more information, industry insights, and the latest news, explore The Lab’s News and Knowledge Hub…

Breakthrough Wave Simulation Software to Boost Metamaterials Development | Scientists Test UV Glass to Disrupt Biofilm Formation in Water | Reusable 3D-Printed Glass Bricks Could Cut Construction Emissions

- Author

- Andrew Yarwood

- Date

- 30/05/2025