Scientists Test UV Glass to Disrupt Biofilm Formation in Water

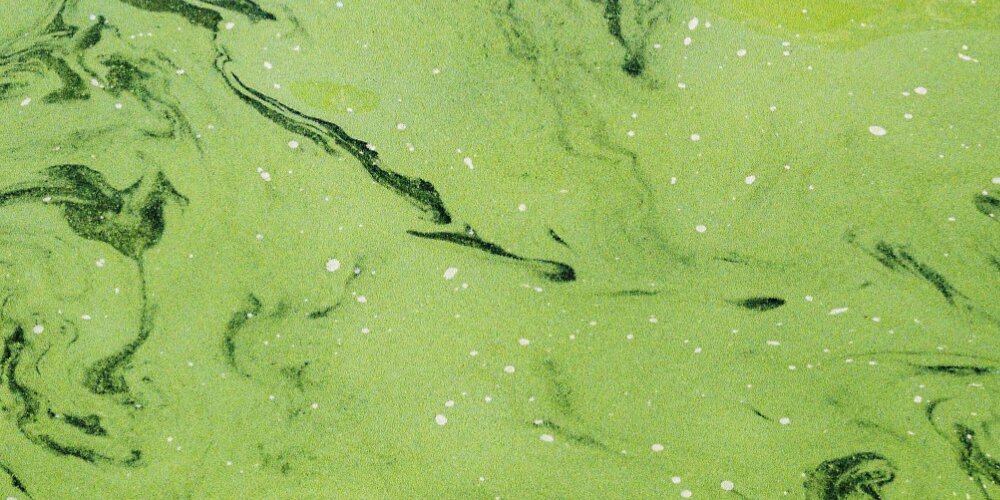

Seawater is home to millions of different microorganisms, including bacteria, algae, and even fungi. Therefore, if you leave something submerged for long enough, it’s unsurprising that it starts to develop a type of film from contact with these tiny lifeforms.

This is usually referred to as a ‘biofilm’ caused by ‘biofouling’ – and isn't as benign as it may seem. Aside from being slimy, biofilms provide a foothold for other, larger organisms like barnacles to grow and reproduce on the submerged material. For smaller pieces of equipment, this may not be a huge problem. However, biofilms and large growths reduce the hydrodynamics of ship hulls as they become less streamlined, which has a negative knock-on effect with regards to fuel efficiency at speed.

Biofilms can also impact the efficacy of marine equipment such as oceanographic equipment, and the transparency of underwater cameras, communication devices, and even windows.

In addition to the practicalities of biofilm formation on marine submersibles, ‘ship biofouling is an important mechanism for the translocation and introduction of non-native species throughout the world, which can impact various economic, ecological, societal, and cultural values’.

Unfortunately, current techniques to prevent biofilm formation have their own issues. For example, some antifouling coatings applied to ship hulls can contain high levels of biocides. Whilst this kills the microorganisms responsible for biofilms, biocides are unable to discriminate between fouling and non-fouling microorganisms, resulting in an adverse effect on underwater ecosystems.

Other coatings don’t use biocides. Instead, they concentrate on using chemical coatings to resist and discourage biofilm formation. However, as they must ‘exhibit long-term mechanical and chemical stability’, these coatings are expensive, time-intensive, and require collaborations between different disciplines.

But, in an interesting new study, a team of researchers and engineers from the University of Massachusetts have explored the merits of using UV-emitting glass to prevent biofilm formation.

UV light has long been proven to ‘prevent organism replication, growth, and infection by damaging the cell’s DNA, RNA, and protein structures’, which would make it the perfect tool to discourage biofilm formation.

Using this foundational idea, the team developed a coating of silica nanoparticles and a clear polymer which was applied to one side of glass. They then attached an ultraviolet LED that shone on the edge of the glass. They found that the light waves were scattered by the nanoparticles in the coating, as these could reflect the radiation without absorbing it – resulting in a uniform spread of the UV.

During a practical test in the waters of Port Canaveral, the team submerged UEG (ultraviolet-emitting glass) slides alongside a control for 20 days, and found that the UEG reduced ‘visible biofilm by 92% and culturable cell count by over 98%’.

The UEG technology represents a valuable leap forward for safer, less destructive biofilm prevention. Firstly, UEG counteracts the conventional problems encountered by using UV disinfection; mainly that distance from the source impacts the efficacy of the radiation. By diffusing the light throughout the glass, the UV light kept the necessary power to eliminate microorganisms without energy losses through the water.

Interestingly, this limited range also means that using glass coatings and UV radiation shouldn’t experience the same issues that biocides have with affecting the local ecosystem – resulting in a less destructive way of protecting submersible equipment like cameras and sensors. In the future, this technology may even be adapted for use on ship hulls, which could help to increase fuel efficiency for ocean transportation.

Dealing with a paint or coating failure?

Then make the experts at The Lab your first call to find you the answers you need.

Paint and coating layers are vital for reducing corrosion, and providing additional protection to your components. When these coatings fail, it’s vital that you understand how and where these elements can be improved for next time.

At The Lab, our team has access to advanced inspection technology to examine and analyse paint or coating samples for contamination, rust, and other faults. Contact our team today to arrange an obligation-free consultation.

Discover paint and coatings analysis from The Lab

For more information, industry insights, and the latest news, explore The Lab’s News and Knowledge Hub…

Can Studying Bubbles Lead to More Efficient Biofuel? | New Plant-Based Plastic Releases Less Microplastic | Researchers Develop ‘Pigment Free’ Paint

- Date

- 01/10/2024